You’ve been tasked with redesigning your operating model—and everything feels like it’s moving at once. People. Processes. Technology—and value stream mapping might not even be something you’ve considered yet. Everyone’s got an opinion, and you’re stuck trying to piece it all together while still hitting targets.

You’ve mapped out processes. You’ve held workshops. But something still feels off. Silos are resurfacing. Delivery is slow. And you’re not sure if your shiny new model is actually helping your customers—or just reshuffling the same problems into a new format.

Here’s the missing piece: you’re designing around structure, not around value.

This is where Value Stream Mapping (VSM) comes in. VSM doesn’t just help you tidy up processes—it helps you see how value really flows through your organisation, from the moment a customer makes a request to the point you deliver. And when you can see that clearly, you can design an operating model that actually works.

In this article, you’ll learn why VSM is your most powerful tool for building smarter, leaner, more customer-focused operating models—and how to start using it before you waste time designing something that looks great on paper but breaks down in practice.

The Real Problem with Most Operating Models

Most operating models don’t fail because the people building them aren’t smart. They fail because they’re built from the inside out.

Here’s what that looks like: teams start with structure—org charts, process flows, capability maps. They define functions, assign responsibilities, and sometimes even throw in a RACI matrix for good measure. On paper, it all looks logical.

But here’s the catch: they’re designing based on how things should work, not how value actually flows.

This leads to three common problems:

- Misaligned priorities.

Teams optimise for their own function, not for end-to-end value delivery. What’s efficient for IT might slow things down for customer support. What’s fast for sales might overload operations.

- Siloed decision-making.

Without a shared understanding of the full value stream, decisions are made in isolation. You end up with duplicated efforts, handoff delays, and a frustrating lack of accountability.

- Invisible waste.

Because you haven’t visualised the full flow from request to delivery, inefficiencies hide in plain sight. Handoffs, rework, waiting times—they’re all baked into the system, but no one’s tracking them.

The result? An operating model that looks clean on a slide but doesn’t work in reality. One that creates more meetings, more handovers, and more friction between teams—without actually delivering better outcomes for your customers.

To fix this, you need a way to zoom out. You need to see the system end to end. That’s exactly what Value Stream Mapping gives you.

Read: Why Knowledge Transfer Often Fails

What Value Stream Mapping Actually Is (and Isn’t)

Let’s clear something up right away: Value Stream Mapping is not just a glorified process map. If you’ve been told “we already do that” because someone’s got a few Visio diagrams lying around, that’s not VSM.

VSM is about flow—specifically, how value flows through your organisation from the moment a customer makes a request to the point you fulfil it.

Think of it as an X-ray for your operating model. It shows the full journey of value delivery, cutting across teams, tools, and silos. More importantly, it doesn’t just show the steps—it shows the delays, the rework, the wait times, and the waste. The stuff you don’t see on a typical process map.

Here’s what VSM is:

- Customer-focused. You start with the customer and work backwards, mapping the value they experience—not just what internal teams do.

- End-to-end. It includes every step, from initial request to final delivery, across departments.

- Quantitative. VSM captures data like cycle times, wait times, and lead times to show where the real friction is.

- Collaborative. It’s not a solo exercise. You bring cross-functional teams together to build the map and see the same picture.

And here’s what it isn’t:

- Just documenting how things work today

- A tool only for manufacturing

- A one-off exercise

- Something you hand off to a junior analyst to “sort out”

Done right, VSM becomes the foundation for designing a better operating model—because it helps you design around what actually matters: delivering value without friction.

Why Value Stream Mapping is a Game Changer for Operating Model Design

When you’re redesigning an operating model, it’s tempting to jump straight into defining roles, processes, and governance structures. But if you haven’t mapped how value actually moves through your system, you’re guessing. That’s where Value Stream Mapping changes everything.

Here’s what makes VSM so powerful:

1. It forces alignment around customer value.

Most operating models are built around functions—HR, finance, IT. VSM shifts the focus to value. It puts the customer at the centre and helps everyone see how their work contributes (or doesn’t) to delivering that value.

Suddenly, it’s not about defending territory. It’s about fixing the flow.

2. It breaks down silos—fast.

When you put a cross-functional team in a room to map a value stream, magic happens. People start to see where the delays and disconnects really are. You move from finger-pointing to problem-solving. That shared understanding becomes the foundation for a more integrated operating model.

3. It highlights where change actually needs to happen.

Without VSM, redesign efforts often focus on the visible parts—org charts, job titles, workflows. VSM surfaces the invisible friction: long lead times, unclear ownership, bottlenecks in approvals. These are the areas where redesign creates real impact.

4. It gives you data—not just opinions.

VSM brings structure and evidence to what’s often an emotional, politically charged process. Instead of arguing over what’s broken, you can point to actual metrics—cycle times, wait times, handoff delays—and design solutions based on reality.

In short, VSM doesn’t just help you design a new model. It helps you design a better one—faster, leaner, and far more likely to deliver the outcomes you care about.

Common Objections to Value Stream Mapping

If you’ve mentioned Value Stream Mapping in a meeting, you’ve probably heard at least one of these:

- “Isn’t that just for manufacturing?”

- “It’s too detailed—we need to stay high-level.”

- “We don’t have time for that.”

Let’s tackle each one—because these objections are common, but they’re also wrong.

“It’s just for manufacturing.”

It’s true VSM came from lean manufacturing, but the core idea—follow the flow of value from request to delivery—applies to any organisation. Whether you’re delivering software, onboarding clients, or resolving customer complaints, you have a value stream. If you want to optimise it, you need to map it.

“We already do process mapping.”

Most process maps show what should happen, or they focus on internal activities. VSM focuses on what actually happens—and ties every step to customer value. It’s about outcomes, not just steps. Process maps tell you what people do. VSM tells you where the system breaks.

“It’s too detailed.”

The irony here? Staying high-level is exactly what causes many operating models to fail. You miss the nuance. You overlook the bottlenecks. VSM doesn’t mean boiling the ocean—it means focusing deeply on a single stream of value to learn where real change is needed.

“We don’t have time.”

If you don’t have time to understand how your business creates value, you don’t have time to redesign it. VSM might feel like a time investment upfront, but it saves you from months of trial-and-error later. Think of it as sharpening the axe before you swing.

The bottom line? If you’re serious about building an operating model that works, you can’t afford not to use VSM.

How to Integrate Value Stream Mapping Into Your Operating Model Design Process

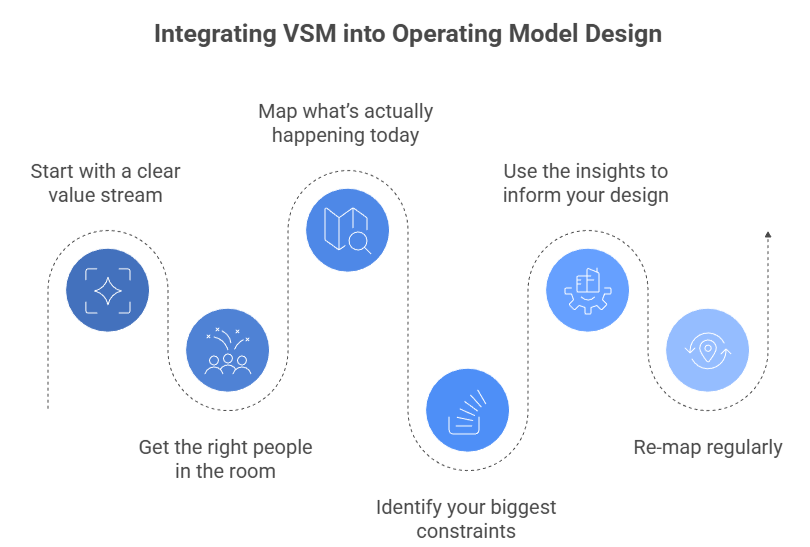

You’re sold on the value of Value Stream Mapping—but how do you actually use it when redesigning your operating model? Here’s a practical approach that won’t just create another slide deck, but actually drives better design decisions.

1. Start with a clear value stream.

Don’t try to map everything at once. Choose one high-impact value stream—like onboarding a new customer or fulfilling an order. Focus on what matters most to your end users or customers.

2. Get the right people in the room.

This isn’t something a single department can do in isolation. Bring together a cross-functional team that touches the value stream from end to end—sales, ops, IT, finance, compliance, customer support. Everyone needs to see the same system.

3. Map what’s actually happening today.

Use real data and real stories—not assumptions. Capture every step, wait time, rework loop, and handoff. Annotate delays, blockers, and pain points as you go. This isn’t about perfection—it’s about visibility.

4. Identify your biggest constraints.

Once the current state is mapped, look for the moments where flow breaks down. These are your leverage points—places where targeted change will create the biggest impact.

5. Use the insights to inform your design.

Now you can begin building your operating model with the right priorities in mind. Structure roles, teams, and systems around the flow of value—not internal hierarchies or departmental lines.

6. Re-map regularly.

VSM isn’t a one-and-done tool. As your organisation evolves, your value streams will too. Use VSM as a living part of your design toolkit to continuously improve how your business delivers.

When you lead with VSM, you’re not just redesigning an operating model—you’re redesigning how your organisation thinks about value, collaboration, and improvement.

Frequently Asked Questions About Value Stream Mapping and Operating Model Design

Q: Isn’t Value Stream Mapping too detailed for strategic work?

A: Not at all. VSM gives you strategic insight because it dives into the detail. It helps you spot systemic issues that surface-level analysis misses. You don’t need to map every step of every process—just the key value streams that define how your business delivers.

Q: How long does a Value Stream Mapping exercise take?

A: A typical value stream mapping session for one end-to-end flow can take anywhere from a few hours to a couple of days, depending on complexity. The payoff? Clarity that can save weeks or even months of rework down the line.

Q: Who should lead the Value Stream Mapping effort?

A: Ideally, someone with a strong grasp of systems thinking and facilitation—often a transformation lead, enterprise architect, or lean practitioner. But success depends less on the facilitator and more on assembling the right cross-functional team.

Q: Can VSM work in service-based or digital businesses?

A: Absolutely. Whether you’re running a bank, a software company, or a logistics operation, value still flows—and often gets stuck. VSM is as powerful in digital and service environments as it is in manufacturing.

Q: What’s the best way to document a value stream map?

A: You can start with pen and paper or whiteboards—it’s about shared understanding, not perfect visuals. Later, you can digitise it using tools like Miro, Lucidchart, or specialised lean software. Just don’t let tooling slow you down.

Q: What’s the difference between VSM and a customer journey map?

A: A customer journey map focuses on the user’s emotional and experiential journey. A VSM focuses on internal flow and operational performance. They’re complementary tools—you can use both to align experience with delivery.

Final Thoughts: Don’t Build Blind

Redesigning an operating model without Value Stream Mapping is like trying to renovate a house without ever looking at the plumbing or wiring. You might make it look good on the surface—but underneath, the problems remain.

VSM gives you sight. It shows you how your business really works—where value flows, where it stalls, and where friction is costing you time, money, and trust. More importantly, it brings people together around a shared picture of reality—one that can actually drive change.

So before you launch your next transformation, pause. Don’t start with structure. Start with flow. Map your value streams. Find the friction. Then build your operating model around what truly matters: delivering value, faster, with less waste and more clarity.

If you want your operating model to work in practice—not just in theory—don’t build blind. Map first.